What is Melt Flow Index?

Melt flow measurement test can perform melt flow characterization of plastic raw materials, products and recycling granules in accordance with TS EN ISO 1133, ASTM D 1238 standards. The product or raw material simulates the molten excess behavior of the polymer. MFR Test: It is a mass measurement method. The samples are loaded from the mold to a certain mass with an accuracy of 0.1 mg and the mfr value is calculated. MVR test is a displacement measurement method.

Importance of Testing Plastic Melt Flow Index

- The height of the melt refers to the performance of the plastic. The plastic raw material generally has a high melt index, and the fluidity is large, the molding process is convenient, the hardness and barrier property are good; impact resistance property, environmental stress cracking resistance property, external property and chemical environment resistance property are weak; melting index, breaking strength, hardness, toughness and aging stability are smaller.

- Polyester yarn and injection molding are processed in molten state. The viscosity of the melt is one of the most important parameters in its rheological properties and is also the key to ensure product quality.

- The melt index is a parameter characterizing the flow rate of the feedstock through the screw. The viscosity of the polymer is determined for a given shear force and depends on shear and temperature.

- The material with a high melt index has a relatively small coefficient of friction with the screw in the extruder, so the output is relatively small. High melting materials usually have more impurity, and the pressure on the machine head is large, which can cause mesh blockage.

- Whether the flow characteristics of the test materials can meet the production requirements, if the test results are not qualified, it cannot be used as raw material for production.

Standards

In the industry, the most common standards used in MFI testing are ISO 1133 and ASTM D1238 standards.

Difference Between ISO 1133 and ASTM D1238, The ISO 1133 standard requires a preheat time of five minutes, while ASTM D1238 requires a preheat time of seven minutes. The ISO 1133 standard has a starting point of 50mm and requires 30mm of piston travel, while the ASTM D1238 method has a starting point of 46mm and requires 6.35 to 25.4mm of travel.

In Which Industries MFR Testings Is Used?

Plastics are widely used because they have higher strength than other materials; They can be produced as desired, do not have a negative effect under difficult conditions and do not react easily to any chemical.

Because of all these factors, they are widely used in areas such as plastics, food and beverage industry, automotive industries, pharmaceutical industries, chemical industries. Since the usage areas of plastics are so wide, the plastic industry must meet the needs of all the above-mentioned sectors.

MFI, melt flow measurement test is indispensable for the produced plastic to be of the best quality. For this reason, MFI, the melt flow measurement test, is widely used in the plastics industry.

How To Do MFI (Melt Flow Test)?

- The settings section is entered on the screen on the test device, some values belonging to the sample and the test are entered according to the standards.

- According to the entered information, the temperature of the melt flow measuring device rises up to the entered value.

- The number of seconds to cut the sample and the number of samples to be taken from the sample are written in the appropriate spaces on the screen of the device.

- By pressing the Save button, all values are stored in the memory, then the device switches to the MFR test screen by clicking the MFR button in the tests section on the screen.

- The samples are filled into the furnace chamber with a metal funnel, a weight holding cylinder rod is placed on the sample left to melt.

- Appropriate weights are added to the cylindrical bar as specified in the sample standards.

- The samples that become fully molten start to flow from the orifice at the exit of the furnace and the Start Button is pressed as the samples start to flow.

- All subsequent operations are carried out automatically by the device. The melted sample is cut automatically every second the cutting time is reset.

- The cut samples are stored in a protected chamber during the test period without being exposed to dirt and dust.

- At the end of the test, the mass of each sample is measured on a precision balance.

The weights button on the screen of the device is pressed, the mass values of each measured sample are entered on the screen in “grams” and the mfr value of the sample is printed as “grams / minute” on the result screen by taking the average of all values after the final mass value.

Formulas for MFI, MVR

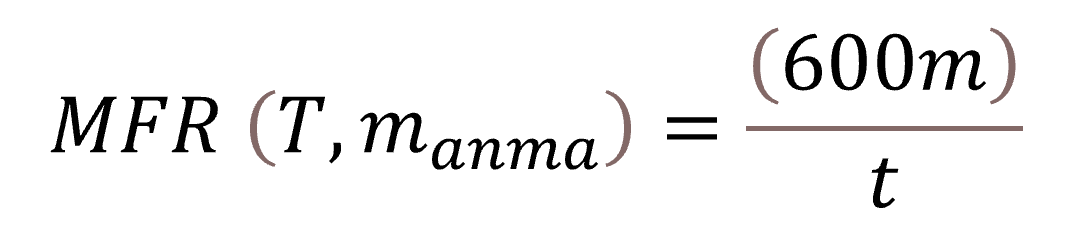

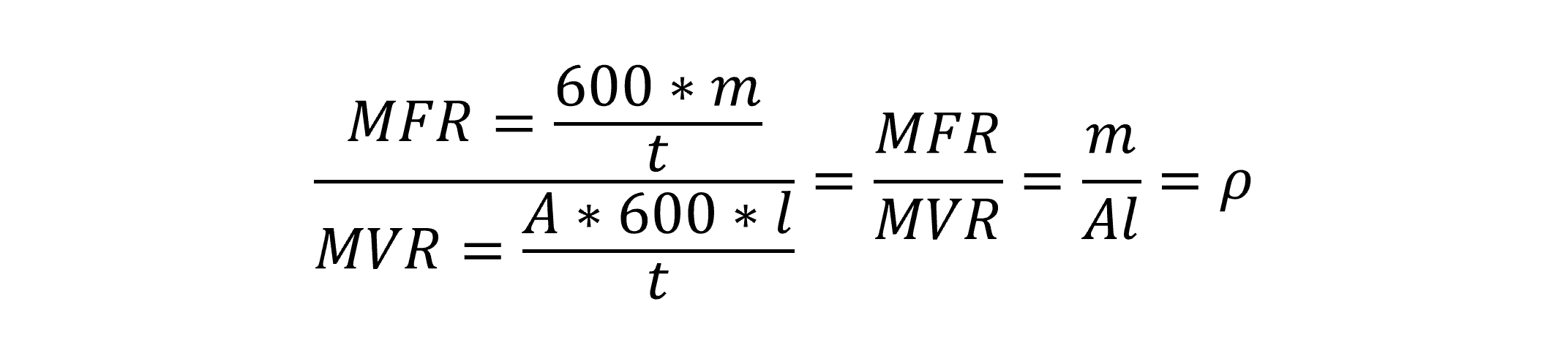

Mass flow rate (MFR) of the material is calculated with the following equation in g/10 minutes:

- T = Test Temprature (℃)

- manma = Rated Load (kg)

- m = Average Mass Of Cut Pieces (g)

- t = Cutting Time Intervals (s)

- Factor used to convert 600 g/s to g/10 minutes (600s)

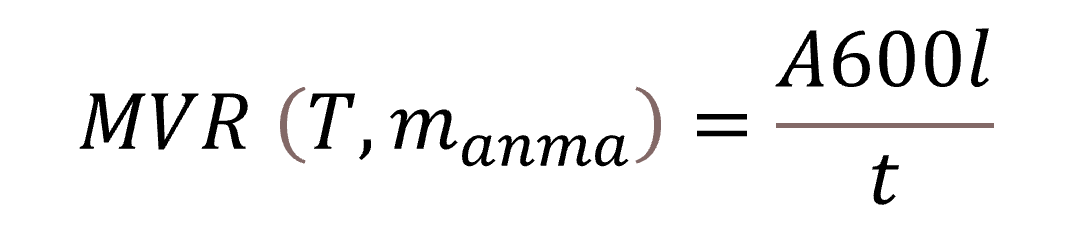

Volumetric Flow Rate of the material (MVR) of the material is calculated with the following equation in g/10 minutes:

- T = Test Temprature (℃)

- manma = Rated Load (kg)

- A = Average cross-sectional area of piston head and cylinder (cm^2)

- t = Predetermined Duration of Measurement or Average Value of Individual Time Measurement

- l = Average Value of Predetermined Distances Taken by the Piston (cm)

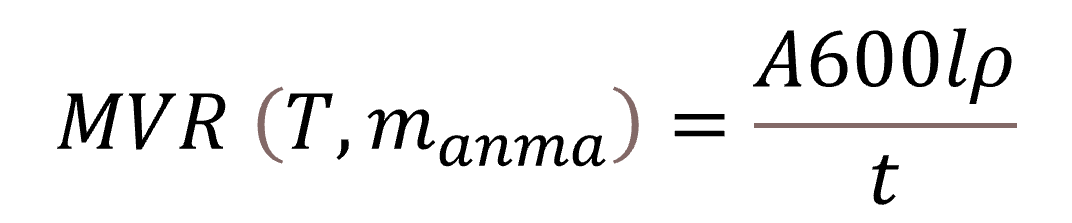

The Volumetric Flow Rate (MVR) of the material is calculated in g/10 minutes with the following equation:

- T = Test Temprature (℃)

- manma = Rated Load (kg)

- A = Average cross-sectional area of piston head and cylinder (cm²)

- t = Predetermined Duration of Measurement or Average Value of Individual Time Measurement

- l = Average Value of Predetermined Distances Taken by the Piston (cm)

- ρ = Density of the Melt at Test Temperature (g/cm³)

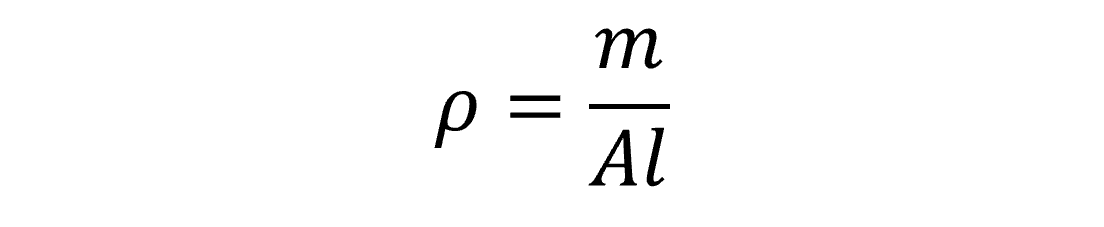

The ρ value is calculated by the following equation:

- m = Mass of the Extruded Substance Determined by Weighing the Piston with a Movement of 1 cm (g)

How Are Test Results Evaluated?

The ratio of the MFR value to the MVR value will give us the density of the material used in the experiments.

At the same time, the measured MFR and MVR values are checked for compliance with the values in the standards of the tested material. As a result of the comparison of the values, if the requirements are met, no action is taken, and if the hysteresis is not met, the plastic design is revised.

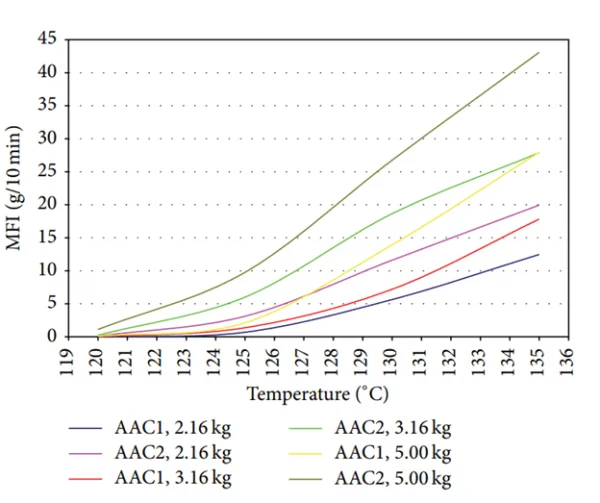

Temperature and Mass Change Graph of Measured MFI Values

The graph above is a graph showing how the MFI value changes when the mass and temperature values of two different plastics change. As can be interpreted from the graph, it is observed that the MFI value increases when the mass and temperature of the material increase. The conclusion to be drawn from this graph is that the experiment should be performed at the temperature and mass values given in the standards. Performing the test in accordance with the standards will give the most accurate result.