What is the Carbon Black Determination Tester?

“Carbon Black” pigment occurs as a result of the chemical reaction of a hydrocarbon fuel with a limited amount of air at a temperature between 1320 and 1540 °C. Carbon Black has a large surface area and is in powder form. By adding this pigment to the products, the resistance of the products against physical effects is increased. It is especially used to strengthen black rubber materials.

Why is the Carbon Black Test Done, Why is the Amount and Distribution Examined Separately?

It is done to check whether the part to be produced is in accordance with the standards.

The amount of carbon black indicates that the samples have high physical strength and improved machinability. The resistance of the samples against the physical forces is important for the material quality.

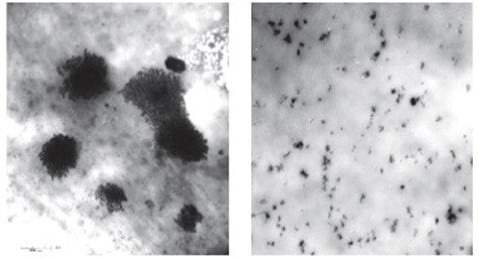

The carbon black distribution and particle size indicate the viscosity, wear resistance and hardness ratio of the sample. As the particle size increases, the viscosity, wear resistance and hardness of the sample decrease.

In order to determine the percentage of carbon in plastic raw materials, “Pyrolysis” is performed in the first stage and “Calcination” is performed in the second stage. The “Carbon Black Percentage” of the sample is calculated from the differences in the mass measurements made before and after each step.

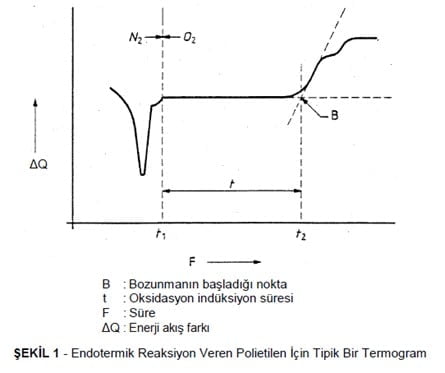

- Pyrolysis: It is the name given to the process of evaporating the plastic in an inert gas environment.

- Inert Gas: It is the name used in this process of nitrogen gas with 99.9% purity (the most used).

- Calcination: It is the name given to the process of reacting oxygen and carbon in the air environment with temperature and removing the carbon.

Standards

In order to get the right result, the following conditions should be applied without ignoring.

- The device should be treated sensitively and kept clean.

- Before starting the tests, nitrogen and air inlet should be installed and checked.

- In order for the test to give accurate results, the sample to be tested must be kept in the desiccator for 24 hours before the test.

- For the temperature to be entered for the 1st stage of the test, a temperature value of 550 °C (+-25 °C) must be entered according to ISO 6964 standards, and this stage should last 40 minutes.

- The purity of the nitrogen gas used should be 99.99%.

- Nitrogen flow rate should be 20 Liters/hour.

- A temperature value of 900 °C (+-50 °C) must be entered for the second stage and this stage should last 10 minutes.

If the test is performed indoors, the hose coming from the gas outlet plug on the oven glass must enter the purification glasses on the device. The harmful gases that may arise during the pure water and silica gel pyrolysis stage in this treatment section should be considered.

In Which Sectors is the Carbon Black Determination Device Used?

- In the Plastic Raw Materials Industry,

- In Plastic Pipe Production and Processing Sector,

- In Recycling Facilities,

- In the Rubber Product Production Sector Carbon Black Determination Device is needed.

Which Samples is the Carbon Black Test Applied?

PE, PP, PVC, PB etc. pipes and fittings, black plastics, “Carbon Black Determination Test” should be applied to all samples with added carbon black.

How to Do the Carbon Black Test?

- The sample and crucible to be used are kept in the desiccator.

- Temperatures required for the test stages are entered into the device from the settings section of the device.

- The crucible is weighed on a precision scale.

- The crucible is slowly placed inside the furnace with a boat so that it is not affected by the particles remaining in the furnace.

- Plugs from which nitrogen gas comes are attached to the furnace glass.

- The first heating phase is started.

- After the first stage is completed and the furnace has cooled, the crucible is placed in the desiccator and left to cool.

- The first stage is weighed and entered into the device.

- The weighed crucible is placed back in the furnace and the second stage is started without the plugs being inserted.

- After the second stage is finished, the crucible is placed in the desiccator and left to cool.

- The last weighing is done and entered into the device.

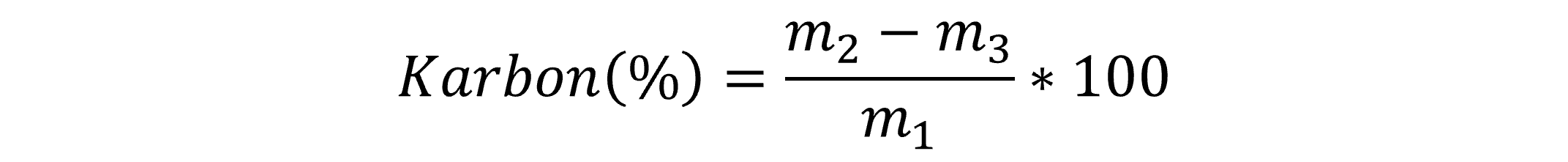

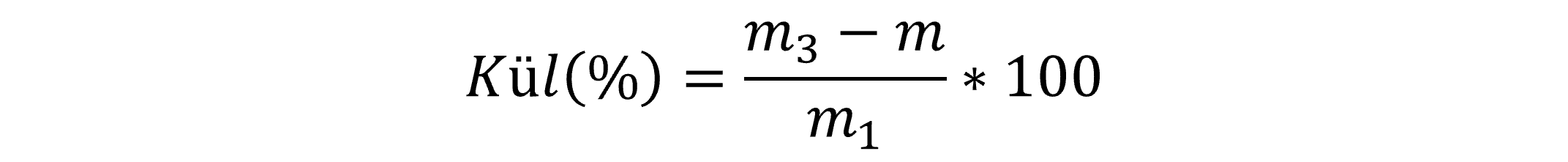

Formulas for Carbon Black and Ash Content

The amount of carbon black and ash is calculated by the formulas below:

- m1 = Mass of Test Sample (g)

- m2 = Total Mass of Test Sample and Boat After Pyrolysis at 550 °C (g)

- m3 = Mass of Sample Boat (with Ash Residue) After Calcination at 900 °C (g)

- m = Mass of Sample boat (g)

- m1 = Mass of Test Sample (g)

- m3 = Mass of Sample Boat (with Ash Residue) After Calcination at 900 °C (g)

How are the Test Results Assessed?

The measured carbon black and ash amount is checked for compliance with the values in the standards of the tested material.