What is Thermal Analysis?

Thermal analysis is the measurement of the changes in the physical properties of the sample, such as melting point, dehydration point, isomer transition point, weight, conductivity, as a function of temperature and time, as a result of a controlled change in the temperature of the sample taken from a substance.

Thermal analysis techniques have various application areas such as structure analysis of materials, purity control, control of thermal constants, quality control, process development. Biological materials, inorganic compounds, metals, alloys, polymers, minerals can be given as examples of substances that can be studied by these techniques.

There are various thermal analysis techniques classified according to the weight change, energy change, size change and emitted gases observed from the material.

What is Oxidation, What Does It Affect?

Oxidation is the reaction of a material with oxygen. When materials undergo oxidation, they lose some of their properties and become unsuitable for use. For example, oxidized iron loses its mechanical strength and becomes unusable. Likewise, oxidized polymers become brittle.

What is OIT (Oxidation Induction Time Determination)?

Differential Scanning Calorimetry (DSC), which is one of the thermal analysis techniques based on energy change, is a technique in which the heat required for heating (endothermic processes), cooling (exothermic processes) or keeping the sample and reference at a constant temperature is measured as a function of temperature and time. It is generally used to evaluate the oxidation stability of various polymeric materials. The OIT test is performed by Differential Scanning Calorimetry (DSC).

What Issues Does DSC Address?

- Material identification

- Amorphous vs. Semi-Crystalline

- Melting Point Analysis

- Glass Transition Analysis

- Material condition

- Contamination

- Molecular Degradation

- Additive Testing

- Residual Stress

- Material Properties

- Crystallinity

- Cure state

DSC is a powerful technique for identifying and diagnosing problems with polymeric components, but it has some limitations.

- Interpretation of results is highly dependent on the analyst experience.

- The region from which the sample was taken may not be representative of the entire piece.

- Machine is highly sensitive.

- Cannot distinguish between samples with similar melting points/glass transition.

It is a standard test used to measure the oxidation stability level of the material, that is, its resistance to oxidation, by determining the time taken until the onset of oxidative decomposition. It measures and evaluates the oxidation stability of materials and the performance of stabilizers much faster than conventional methods.

The oxidation induction time depends on the temperature, the surface area of the sample and the class of the sampled material. As the temperature increases, the oxidation induction time becomes shorter as the decomposition accelerates. The oxidation induction temperature depends on the heating rate and the surface area of the sample. The higher the heating rate, the higher the oxidation induction temperature.

In order to ensure test sensitivity, the sample amount should be maximum 50 mg. In addition, it is necessary to provide a heating environment that will not cause a chemical reaction.

AL-DSC/OIT Properties

- Temperature range is between +25/+350°C

- Temperature resolution ±0.02°C

- Temperature accuracy ±0.2 °C

- The sample amount is max 50 mg

- Heating rate 0.01 – 500 °C / min

- Calorimeter accuracy < ±0.3 %

- Calorimeter sensitivity 0.35 mW

- It is produced according to TS EN ISO 11357 – 1, TS EN ISO 11357 – 6 standards.

ISO 11357 is used for quality assurance purposes, routine inspections of raw materials and finished products to determine the comparable data required for data sheets or databases. It cites several DSC methods for thermal analysis of polymers and polymer mixtures. According to this standard, the substances in which DSC methods are used are thermoplastics, thermosets and elastomers. It is aimed at the observation and measurement of various properties of these substances, such as physical transitions, chemical reactions, heat capacity and oxidation stability.

ISO 11357-6, part of the ISO 11357 standard, describes the evaluation by measuring the oxidation induction time of plastic pulp material in a certain formulation. In the ISO 11357-6 standard, reference is made to the ISO 293, ISO 294-3, ISO 472, ISO 1872-2, ISO 1873-2, ISO 8986-2 and ISO 11357-1 standards.

How to Do the OIT Test?

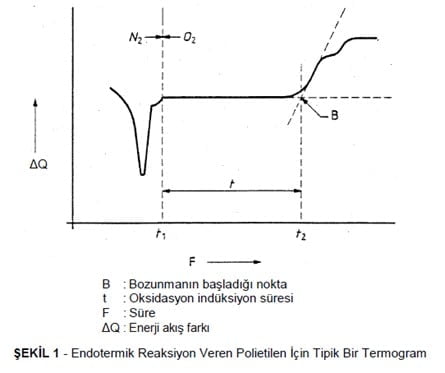

A test piece with a smooth surface is cut from the sample to be tested, in a size and shape to fit inside the capsule. The test piece is placed in an open or ventilable aluminum container in good contact with the container. This aluminum cup and an empty aluminum reference cup are placed inside the machine. A nitrogen flow of 50 ml/min ± 10% is provided from the device until time. The sample and reference are heated at a constant rate in an atmosphere of nitrogen gas and the temperature is kept constant. When the desired temperature is reached, an oxygen flow of 50 ml/min ± 10% is provided at time

. The time elapsed from the time of transition to the oxygen atmosphere (

) to the starting point of exothermic oxidation (

) is measured. This is the oxidation induction time of the sample and is denoted by

. The oxidation time is expressed in minutes.

In order to obtain accurate and reproducible OIT data, the following conditions must be met:

- Stable isothermal temperature

- Constant sample morphology, geometry and weight

- Reliable and consistent purge gas flow rate